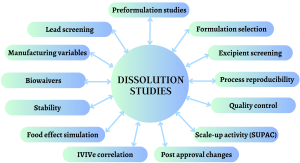

Pharmaceutical Dissolution Testing is a vital tool that quantifies the rate at which the active ingredient of a medication is released in a controlled lab setting that simulates the conditions within the human body. This testing method is crucial in drug development and manufacturing, providing the only standardized approach to generate data that can predict bioavailability (which indirectly denotes therapeutic effectiveness), establish the stability of the dosage form (ensuring safety of the drug product), and indicate any changes in manufacturing processes (which could significantly impact product performance).

Dissolution testing is indispensable in the manufacturing process of drug products as it validates several crucial aspects:

- Thorough evaluation of drug product bioequivalence.

- Confirmation and assurance of bioavailability where relevant.

- Consistency of manufacturing, ensuring the product matches previous batches and is within acceptable parameters.

- Stability of the product over its specified shelf life without any degradation.

- Continuous control over the manufacturing process.

To accurately simulate in-vivo conditions in a dissolution test, the selection of test apparatus and method parameters, such as the composition of the medium, pH levels, and sample collection frequency, must be adapted to the dosage form and the specific objectives of the test. The USP offers guidelines on apparatus types and procedural suggestions for testing immediate, extended, and delayed-release dosage forms. The list of officially recognized apparatus for pharmaceutical dissolution testing includes USP 1 baskets, USP 2 paddles, USP 3 reciprocating cylinders, USP 4 flow-through cell, USP 5 paddle over disk, USP 6 cylinders, and USP 7 reciprocating holders.

Partnering with Synergy Bioscience assures precise, dependable, and timely dissolution testing outcomes. This is due to our team of highly trained scientists, our advanced technology and equipment, and our competitive pricing structure. Choose Synergy Bioscience for all your pharmaceutical dissolution testing requirements and rely on our comprehensive knowledge of dissolution testing apparatus and methodologies.